Unique selling points

- Removal of both hardness and organic matter

- Reuse of local by-products

- Increase of materials symbiosis between industry and utility

- Reduction of waste disposal

Description of the technology

Hard water is any type of water that contains more minerals than average tap water. Mostly it has to do with elevated levels of calcium and magnesium. Hence, water softening is a process in which the ions of calcium and magnesium are removed (Ordonez et al. 2012).

When treating water with a high hardness, a softening process could also reduce the conductivity of the water, avoiding reaching very high values of conductivity after the coagulation phase (Ordonez et al. 2012). Chemical precipitation is one of the more common methods used to soften water. Chemical additives such as lime or soda induce the formation of insoluble precipitates that are readily discharged from the water to obtain soft water (Wang et al. 2019):

MgSO4 + Ca(OH)2 → Mg(OH)2↓ + CaSO4

CaSO4 + Na2CO3 → CaCO3↓ + Na2SO4

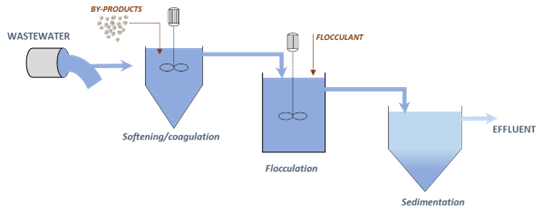

These precipitates are then removed by conventional processes of coagulation/flocculation, sedimentation, and filtration.

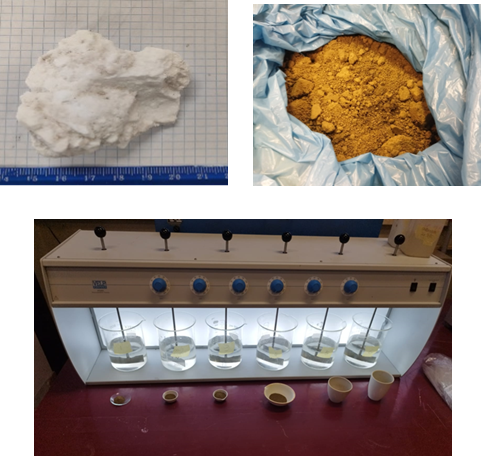

In this application, industrial by-products will be tested and used as softening agents or coagulants:

- Sodium Carbonate (Na2CO3): off-specification waste material of the "Soda Solvay Light" produced and commercialized by Solvay.

- Precotto: partially cooked calcareous rocks produced by Solvay

- Iron and alum sludge from drinking water treatment plants

Sodium Carbonate and Lime have been used in softening/coagulation/flocculation processes, mainly to reduce hardness in wastewater streams. A softening step to remove impurity ions (i.e., Ca2+ and Mg2+) from hypersaline coal chemical wastewater used Sodium Carbonate with a dosage of 1.3 g/L Na2CO3 (Chen et al. 2021). Similarly, a combination of coagulation, softening and flocculation was applied to treat the concentrated stream of a reverse osmosis unit. Different polyaluminium chlorides and one ferric salt were used as coagulants, lime was added as softener, and two polymers (anionic and cationic polyacrylamides) were tested as flocculants. In this case, thanks to Lime dosage conductivity was reduced through the removal of Ca2+ and Mg2+ (Ordonez et al. 2012).

Sludge is a residual of the drinking water treatment processes, which could be reused for wastewater treatment. In particular, alum-based sludge (AbS) contains a large portion of insoluble alum hydroxides, and the possibility to reuse alum-rich sludge may be a practical solution to reduce the problems associated with its handling and disposal (Foroughi et al. 2018). Alum rich coagulation sludge could be used in soil amendment, in construction industry, in constructed wetland, for phosphate removal and for cement production, while Iron rich coagulation sludge could be used for soil amendment, in construction industry, in constructed wetland, as raw material for clay brick and cement production and potentially also for sulfide control in sewers and digester (Pikaar et al. 2022). Water treatment sludge has already been successfully used to improve the removal efficiencies of suspended solids (SS) and chemical oxygen demand (COD) in wastewater as well as to enhance the removal of natural organic matter (NOM) in surface water (Xu et al. 2016; Foroughi et al. 2018). In a further application, combinations of water treatment sludge with fresh coagulant proved to obtain a substantially higher COD removal compared to the removal obtained by fresh coagulant alone during wastewater treatment (Nair & Ahammed 2015).

Flow scheme of the technology

Synergetic effects and motivation for the implementation of the technology

- Recovery of industrial by-products

The application of this technology in Aretusa case study has the purpose to increase the sustainability of the wastewater treatment process by maximizing the circularity of reagents and materials used in the plant. In this way, in fact, residuals of the local industrial production cycle are reused in the Aretusa plant to increase the quality of the treated wastewater and, consequently, the sustainability for the water reuse by Solvay Industry. Moreover, the Aretusa plant is located in the same area of Solvay plant, and this fact contributes to further reduce costs and impacts for material transportation and production. Finally, finding a useful application for these residuals will save costs for disposal and will reduce the waste production.

- Removal of both hardness and organic matter

Technology requirements and operating conditions

A typical softening/coagulation/flocculation process involves three treatment steps that require different reaction times and mixing velocity. Coagulation and softening are usually short in time and have high mixing velocities, while lower mixing velocities are applied during flocculation to avoid the breakage of the formed flocs.

Tab. 1 Typical ranges for operating parameters

|

Parameter |

Units |

Min |

Max |

Reference |

|

Coagulation time |

min |

1 |

5 |

|

|

Coagulation mixing velocity |

rpm |

100 |

600 |

El-Gohary & Tawfik 2009; Ordonez et al. 2012; Foroughi et al. 2018 |

|

Softening time |

min |

2 |

|

|

|

Softening mixing velocity |

rpm |

|

200 |

|

|

Flocculation time |

min |

20 |

30 |

|

|

Flocculation mixing velocity |

rpm |

20 |

50 |

Ordonez et al. 2012; El-Gohary & Tawfik 2009; Foroughi et al. 2018 |

|

Sedimentation time |

min |

30 |

60 |

Case Study applying the technology

Publications

- Chen, F., Zhang, Z., Zeng, F., Yang, Y., Li, X., Pilot-scale treatment of hypersaline coal chemical wastewater with zero liquid discharge, 2021

- El-Gohary, F., Tawfik, A., Decolorization and COD reduction of disperse and reactive dyes wastewater using chemical-coagulation followed by sequential batch reactor (SBR) process, 2009

- Foroughi, M., Chavoshi, S., Bagheri, M., Yetilmezsoy, K., Samadi, M. T., Alum-based sludge (AbS) recycling for turbidity removal in drinking water treatment: an insight into statistical, technical, and health related standpoints, 2018

- Georgiou, D., Aivazidis, A., Hatiras, J., Gimouhopoulos, K., Treatment of cotton textile wastewater using lime and ferrous sulfate, 2003

- Ilje Pikaar ; Katrin Doederer ; Tessa van den Brand ; Olaf van der Kolk ; Wolfgang Gernjak, Chapter 3: Resource recovery from drinking water production facilities: what and how much is there?, 2022

- Nair, A.T., Ahammed, M. M., The reuse of water treatment sludge as a coagulant for post-treatment of UASB reactor treating urban wastewater, 2015

- Ordonez, R., Morel, A., Hermosilla, D., Blanco, A., Combining coagulation, softening and flocculation to dispose reverse osmosis retentates, 2012

- Sher, F., Malik, A., Liu, H., Industrial polymer effluent treatment by chemical coagulation and flocculation., 2013

- Wang, Y., Guo, X., Bai, Y., Sun, X., Effective removal of calcium and magnesium sulfates from wastewater in the rare earth industry, 2019

- Xu, Y., Chen, T., Cui, F., Shi, W., Effect of reused alum-humic-flocs on coagulation performance and floc characteristics formed by aluminum salt coagulants in humic-acid water, 2016