Unique selling points

- Reuse of by-products

- Low-cost carbonaceous adsorbent

- Monitoring system with online measure of COD (UV and Fluorescence), pH and conductivity

- Test for emerging contaminants

Description of the technology

Hydrochars are carbon-rich porous material obtained by hydrothermal carbonization (HTC) of feedstock materials. HTC is a thermochemical process that converts wet biomass into a value-added product (Kazak & Tor 2020). HTC has been applied to treat numerous typologies of biomass, such as green waste (Puccini et al. 2017), sunflower stem, walnut shell, olive stone, vinasse, red mud, rattan stalks, rice straw, argan nut,(Román et al. 2013, Kazak & Tor 2020, Zbair et al. 2020, Mohamed et al. 2017 and Islam et al. 2017) and waste and sludge produced in wastewater treatment plants (Kirschhöfer et al. 2016, Benstoem et al. 2018 and Tasca et al. 2020). It is underlined that in 2022, Italian national guidelines have been published (UNI 11853:2022) regarding the specifications of the material obtained from the hydrothermal carbonization (HTC) treatment of the residues of urban wastewater treatment plants or industrial sludge with an organic matrix.

One of the most promising applications for the reuse of hydrochars is the adsorption process. However, this recovered material to be performant in contaminant removal needs to be activated to increase pore size and surface area. In fact, the hydrocarbons usually suffer from a low specific area with BET surface area < 10 m2 g-1 (Chen et al. 2017). The activation of hydrochars can be achieved by two different methods, namely physical and chemical activation. During the physical activation, an activating agent (steam, carbon dioxide, air or a combination thereof) gasifies at elevated temperatures part of the carbon structure and creates porosities. In the chemical activation process, the feedstock is first impregnated with a reagent (KOH, ZnCl2, H3PO4, K2CO3, etc.) and then heated in an inert atmosphere (Miliotti et al. 2020). Hydrochar has been reported to have high adsorption capacities for heavy metals and polar/non-polar organic pollutants in aqueous solutions (Kazak & Tor 2020, Puccini et al. 2017, Zbair et al. 2020, Benstoem et al. 2018).

In ULTIMATE project, Hydrochar produced by hydrothermal carbonization of sewage sludge of municipal wastewater treatment plants (WWTP) will be utilized to remove COD and emerging contaminants. The pilot will be instrumented with online meters for the monitoring of pH, conductivity and COD (in this case fluorescence and UV absorbance at 254 nm will be used as surrogate parameters). The pilot will be composed of four adsorption columns of different dimensions. The Hydrochar has been activated through a slow pyrolysis process at a temperature of 450°C with a residence time of 90 min.

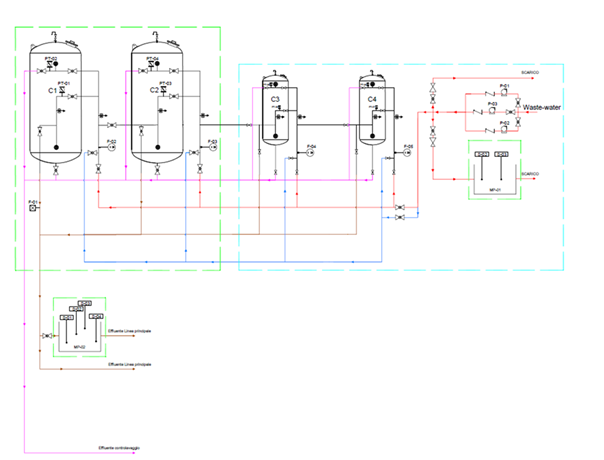

Flow scheme of the technology

Synergetic effects and motivation for the implementation of the technology

- Recovery of by-products

In the scientific literature, hydrochar has been proposed as a low-cost carbonaceous adsorbent for pollutants removal from water (Kazak & Tor 2020). The reutilization of hydrochar produced from sewage sludge will increase the circularity of the wastewater treatment process reducing costs and produced wastes.

- Monitoring system

In the design of the pilot specific attention was given to the monitoring system. Different sensors will be installed along with a control unit in order to allow a real-time monitoring of the adsorption process.

Technology requirements and operating conditions

The adsorption columns have been designed in order to have an Empty Bed Contact Time in the range of 5-30 minutes and a hydraulic loading rate of 5-15 m/h.

Tab. 1 Typical ranges for operating parameters

|

Parameter |

Units |

Min |

Max |

Reference |

|

EBCT |

min |

5 |

30 |

Metcalf & Eddy 2014 |

|

Hydraulic loading rate |

m/h |

10 |

6 |

Metcalf & Eddy 2014 |

Key performance indicators

|

Parameter |

Units |

Value |

References |

|

Adsorption capacity compared to commercially available materials |

% |

TBD |

|

|

Reduced waste production |

kg/ton |

TBD |

|

Case Study applying the technology

Publications

- Benstoem, F., Becker, G., Firk, J., Kaless, M., Wuest, D., Pinnekamp, J., Kruse, A., Elimination of micropollutants by activated carbon produced from fibers taken from wastewater screenings using hydrothermal carbonization, 2018

- Islam, M. A., Ahmed, M. J., Khanday, W. A., Asif, M., Hameed, B. H., Mesoporous activated carbon prepared from NaOH activation of rattan (Lacosperma secundiflorum) hydrochar for methylene blue removal, 2017

- Kazak, O., Tor, A., In situ preparation of magnetic hydrochar by co-hydrothermal treatment of waste vinasse with red mud and its adsorption property for Pb(II) in aqueous solution, 2020

- Kirschhöfer, F., Sahin, O., Becker, G. C., Meffert, F., Nusser, M., Anderer, G., Kusche, S., Klaeusli, T., Kruse, A., Brenner-Weiss, G., Wastewater treatment – adsorption of organic micropollutants on activated HTC-carbon derived from sewage sludge, 2016

- Metcalf & Eddy, Wastewater Engineering: Treatment and Resource Recovery, 2014

- Miliotti, E., Rosi, L., Bettucci, L., Lotti, G., Rizzo, A. M., Chiaramonti, D., Characterization of Chemically and Physically Activated Carbons from Lignocellulosic Ethanol Lignin-Rich Stream via Hydrothermal Carbonization and Slow Pyrolysis Pretreatment, 2017

- Mohamed, G. M., El-Shafey, O. I., Fathy, N. A., Preparation of Carbonaceous Hydrochar Adsorbents from Cellulose and Lignin Derived from Rice Straw, 2017

- Naves Arnaldos, A., van den Broeke, J., Guleria, T., Bruni, C., Fantone, F., Touloupi, M., Iossifidis, D., Giménez Lorang, A., Sabbah, I., Farah, K., Baransi-Karkaby, K., Pidou, M., Reguer, A., Kleyböcker, A., Jährig, J., Vredenbregt, L., Thisgaard, P., D1.9 Start-up and intermediate results of plant operation from all case studies, 2023

- Puccini, M., Stefanelli, E., Hiltz, M., Seggiani, M., Vitolo, S., Activated Carbon from Hydrochar Produced by Hydrothermal Carbonization of Wastes, 2017

- Román, S., Valente Nabais, J. M., Ledesma, B., González, J.F., Laginhas, C., Titirici, M. M., Production of low-cost adsorbents with tunable surface chemistry by conjunction of hydrothermal carbonization and activation processes, 2013

- Tasca, A. L., Stefanelli, E., Raspolli Galletti, A. M., Gori, R., Mannarino, G., Vitolo, S., Puccini, M., Hydrothermal Carbonization of Sewage Sludge: Analysis of Process Severity and Solid Content, 2020

- Zbair, M., Bottlinger, M., Ainassaari, K., Ojala, S., Stein, O., Keiski, R. L., Bensitel, M., Brahmi, R., Hydrothermal Carbonization of Argan Nut Shell: Functional Mesoporous Carbon with Excellent Performance in the Adsorption of Bisphenol A and Diuron, 2020