Unique selling points

- Release of soluble organic matter leading to higher degradation during anaerobic digestion and thus, enhancing biogas production

- Better dewaterability of digestate and hence, reduction of disposal costs

- Release of phosphate and ammonium from disintegrated organic compounds

Description of the technology

The thermal hydrolysis process (THP) is used as a pre-treatment for anaerobic digestion usually at wastewater treatment plants with a capacity for 100 000 population equivalents and greater. Originally, THP was used to enhance the dewaterability of sludge (Zhen et al. 2017). However, in addition it was shown, that THP improves the solubilisation of the sludge, reduces its viscosity (Bougrier et al. 2006, Higgins et al. 2017, Liu et al. 2019) and increases its biogas yield (Neyens and Baeyens 2003).

Usually excess sludge only or sometimes even mixed sludge consisting of primary and excess sludge are pretreated via THP and disintegrated at temperatures between 60 °C and 180 °C (Zhou et al. 2021). The THP breaks down complex organic compounds and cell structures into more soluble compounds and thus, increases the substrate availability for anaerobic biodegradation.

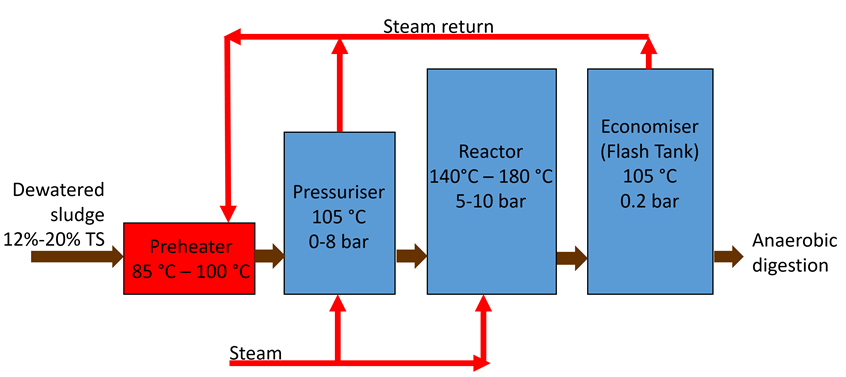

As an example, the high temperature thermal hydrolysis process is described in detail here. Typical high temperatures are between 140°C and 180 °C. In addition, the THP is operated at high pressure conditions usually ranging between 5 and 8 bar. For the sludge disintegration, first the sludge is tempered to 85 °C in a preheater for example by using excess heat from the hydrolysate. Then, the sludge passes through three tanks: (1) the pressuriser, (2) the reactor and the (3) economiser. In the pressuriser, the sludge is further heated to 105 °C and the pressure is increased between 5 and 8 bar. In the reactor, the high pressure is maintained, while the temperature is further increased to around 140 °C or more. In the economiser, the pressure is decreased via a rapid decompression to 0.2 bar, forcing the sludge through a small orifice. Due to high mechanical shear forces with this “flash”, the microbial cell walls are destroyed and thus, soluble organic compounds are released.

Flow scheme of the technology

The flow scheme shows an example for a thermal hydrolysis process with high pressure.

Pictures

Synergetic effects and motivation for the implementation of the technology

- Subsequent anaerobic digestion: increase in methane yield up to 25% due to THP

The THP breaks down complex organic carbon compounds such as microbial cells into soluble compounds. In a subsequent anaerobic digester, microorganisms degrade those soluble compounds resulting in an increase in the methane yield of about 15% – 25% compared to anaerobic digestion without THP (DWA 2014).

- Reduction of the sludge disposal volume and correspondingly their disposal costs

Due to the higher degradation rate in a subsequent anaerobic digester to the THP, the volume of the digestate decreases correspondingly. Furthermore, according to Neyens and Baeyens (2003), the dewaterability is enhanced after THP. Hence, the volume of the dewatered sludge can be reduced reaching a dry matter content of 30% and more due to the better dewaterability and the higher degradation rate during anaerobic digestion (Metcalf et al. 2013, Neyens and Baeyens 2003). Thus, the disposal costs for the dewatered sludge decrease, too. Phothilangka et al. (2008) saved 25% of their disposal costs.

- THP enables the operation of the downstream digestion at higher dry solids (DS) contents and with higher organic loading rates

THP leads to a lower viscosity (Higgins et al. 2017) enabling the operation of the downstream digestion process at higher DS contents still achieving favourable mixing conditions. Furthermore, the enhanced biodegradability leads to higher digestion rates and thus, to lower required hydraulic retention times allowing for the operation at higher organic loading rates (Pilli et al. 2015).

- Release of ammonium and phosphate for a subsequent nutrient recovery

The disintegration process in the THP enhances the performance of the anaerobic digestion process also resulting in a higher ammonium and phosphate release into the liquid phase. Due to the accumulation of ammonium and phosphate, the resulting liquor is very suitable for a subsequent nutrient recovery such as ammonium (air or membrane) stripping or struvite production.

- Sterilized sludge after high temperature THP

Due to high temperatures between 130 °C and 180 °C and the rapid decompression from 6 bar to 0.2 bar, microbial cell walls are destroyed (Pilli et al. 2015) and thus, pathogenic organisms, too.

Technology requirements and operating conditions

Prior to the treatment, the excess sludge is digested in order to reduce its volume and then, it is thickened usually to a total solids content of up to 20%. In order to disintegrate organic compounds such as microbial cells, the sludge must be heated to a range between 60 °C and 180 °C. At temperatures until 100 °C, the process is operated at normal pressure conditions. At high temperatures between >100 °C and 180 °C, the THP is maintained at high pressure conditions between 2 and 9 bar. In detail, for the typical temperature range between 140 °C and 180 °C, the pressure is usually operated between 5 and 6 bars (DWA 2014). The hydraulic retention time usually ranges between 15 and 60 min.

|

Parameter |

Units |

Min |

Max |

Reference |

|

Total solids (sludge feed) |

% |

12 |

20 |

DWA 2014, NextGen D1.4 (in prep.) |

|

Temperature |

°C |

60 |

180 |

Zhou et al. 2021, DWA 2014; Neyens and Baeyens 2003 |

|

High pressure conditions (T > 100°C) |

bar |

2 |

10 |

Zhou et al. 2021, Pilli et al. 2015, DWA 2014 |

|

Hydraulic retention time |

min |

15 |

60 |

Key performance indicators

|

Parameter |

Units |

Min |

Max |

Reference |

|

Increase in biogas yield in subsequent digestion |

% |

15 |

25 |

DWA 2014, NextGen D1.4 (in prep.) |

|

Degradation in subsequent digestion |

% |

60 |

65 |

DWA 2014, Barber 2016 |

|

Dry solids contents after dewatering due to an increased dewaterability |

% |

30 |

52 |

Links to related topics and similar reference projects

|

Processes/ technologies |

Reference |

|

Anaerobic digestion & THP |

Case Study applying the technology

Publications

- Barber, W., Thermal hydrolysis for sewage treatment: a critical review, 2014

- Bougrier, C., Albasi, C., Delgenès, J., Carrère, H., Effect of ultrasonic, thermal and ozone pre-treatments on waste activated sludge solubilisation and anaerobic biodegradability, 2006

- DWA 2014, Merkblatt DWA-M 302 Klärschlammdesintegration, 2014

- Higgins, M., Beightol, S., Mandahar, U., Suzuki, R., Xiao, S., Lu, H., Le, T., Mah, J., Pathak, B., DeClippeleir, H., Novak, J., Al-Omari, A., Murthy, S., Pretreatment of a primary and secondary sludge blend at different thermal hydrolysis temperatures: impacts on anaerobic digestion, dewatering and filtrate characteristics, 2017

- Kim, J., Hofman, J., Kenyeres, I., Poor-Pocsi, E., Kleyböcker, A., Heinze, J., Kraus, F., Soares, A., Paissoni, E., Vale, P., Palmer, M., Bloemendal, M., Beernink, S., Ros, S., Hartog, N., Frijns, J., D1.4 (2022) New approaches and best practices for closing the energy cycle in the water sector, 2022

- Liu, X., Xu, Q., Wang, D., Yang, Q., Wu, Y., Li, Y., Fu, Q., Yang, F., Liu, Y., Ni, B.J., Wang, Q., Li, X., Thermal-alkaline pretreatment of polyacrylamide flocculated waste activated sludge: process optimization and effects on anaerobic digestion and polyacrylamide degradation, 2019

- Metcalf & Eddy, Inc., Tchobanoglous, G., Stensel, H., Tsuchihashi, R. Burton, F., Wastewater Engineering: Treatment and Resource Recovery, 2013

- Neyens, E., Baeyens, J., A review of thermal sludge pre-treatment processes to improve dewaterability, 2003

- Phothilangka, P., Schoen, M., Wett, B., Benefits and drawbacks of thermal pre-hydrolysis for operational performance of wastewater treatment plants, 2008

- Pilli, S., Yan, S., Tyagi, R., Surampalli, R., Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review, 2015

- Zhen, G., Lu, X., Kato, H., Zhao, Y., Li, Y., Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives, 2017

- Zhou, P., Meshref, M., Dhar, B., Optimization of thermal hydrolysis process for enhancing anaerobic digestion in a wastewater treatment plant with existing primary sludge fermentation, 2021