Description

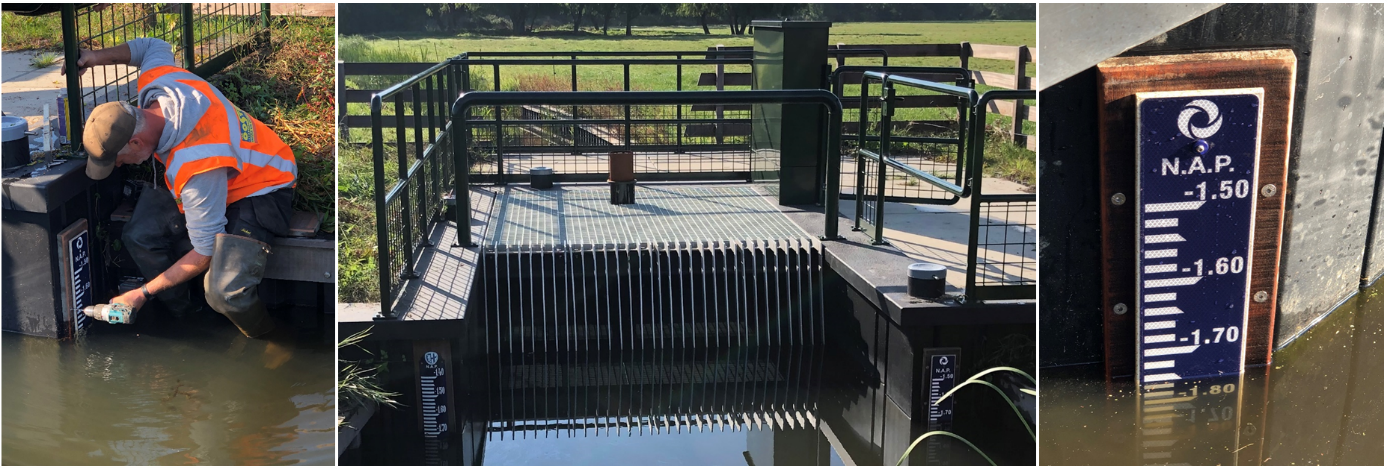

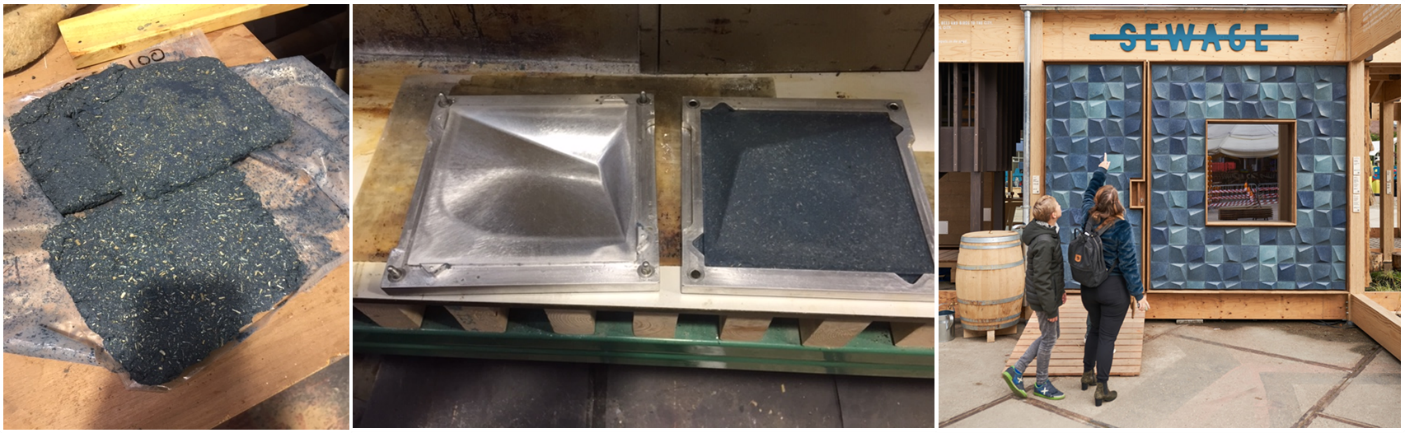

In the Wider Uptake project, NPSP, Waternet and TU Delft are working on the availability of biocomposite materials and products based on raw materials recovered from the water cycle. This case study includes the development, production and demonstration of thermosetting Bulk Moulding Compound (BMC) materials consisting of residual flows from wastewater treatment and the drinking water production process, clippings from surface water management and commercially available bio-resins. The raw materials selected and used in this project include reed and grass fibres from the water board, recycled calcite from the drinking water softening process and cellulose fibres from the wastewater treatment plant (WWTP). From this, together with resins and fillers from agricultural waste, a number of biocomposite materials have been developed with an increasing bio- and waste-based content up to 100%. These can be fully reused in its own production process at the end of their lifespan, making them fully circular. The developed materials were then used for demonstration in prototype products such as 3D facade panels, in bank protection elements, in nautical signs and water level scales, in a spherical design lamp and as construction material in a weir, with the common goal of displacing less sustainable materials (such as aluminium and hardwood) used today for these applications. An integral part of the work was to assess health and environmental risks, circularity and efficiency and commercial viability of the developed biocomposite materials and prototype products.

Requirements and conditions

The development and production of bio-composites with natural and waste based ingredients and commercial positioning of these as an alternative to conventional materials poses challenges of a technical, operational and commercial nature. After all, a proven supply chain and partner ecosystem with critical volumes for these do not yet exist, where the conventional materials we want to displace are widely used with related efficiencies. A few requirements and challenges are highlighted below.

Requirement 1: Selected raw materials must be available and meet the required technical specifications for use in BMC composites, be clean, of consistent quality, and marketable in accordance with commercial and regulatory requirements (which implies that these are supported by relevant data and declarations, and not treated as mere waste).

Constraints:

- Natural and waste based ingredients are not as pure as synthetic materials and their properties can vary according to the place of origin and seasonal influences, and for the natural fibres the weather conditions during growth and collection.

- Minimum processing and ordering volumes that often apply to raw materials, combined with best-before dates, can create barriers to scaling up new materials. These challenges can be managed, but they have an impact on costs and thus on competitiveness of the new materials.

Requirement 2: Developed biocomposites can be produced cost-effectively with reproducibly good mechanical properties as the minimum required for selected applications.

Constraints:

- The properties of natural waste fibres and bio-based resins are generally less than those of synthetic resins and fibres and related biocomposites may therefore require more material to provide comparable performance (as required by the product application).

- Producing bio-based and waste-based composites is technically more challenging than conventional composites, as the ingredients are generally less consistent and predictable, requiring more attention and tuning to make them work.

- The market volumes of bio-based and waste-based composites still need to scale up to achieve optimal chain and cost efficiency. The developed materials and products score mainly on sustainability (because of bio and waste-based content and circular use), but generally lag on physical properties and cost per equal weight. With smart material-efficient designs, the price differences may be reduced in select applications, but not closed. A form of shadow pricing could stimulate the competitiveness and thereby upscaling of sustainable biocomposites, but this would have an overall price-increasing effect.

Requirement 3: For wider uptake of the developed biocomposites, we will be looking for (volume) manufacturers who are willing and capable to work with the bio-based and waste-based materials.

Constraints:

- Established composite manufacturers show hesitant to use new bio-based and waste-based raw materials in their production process. These materials are not consistent batch over batch and are therefore potentially disruptive to a continuous production process. Moreover, this would lead to greater diversification in the sourcing of materials, resulting in associated costs and investments. To fill this gap in the production and scale-up of these new materials, NPSP had no choice but to take on production themselves.

Requirement 4: For a sustainable end product to be commercially viable, it must be considered feasible at scale to achieve a price within 10% of comparable products that are demonstrably less sustainable and/or have a price differential that is fully offset by shadow prices for social and environmental impacts (i.e. be fully competitive on a true pricing basis).

Constraints:

- The new raw materials and biocomposites made thereof lack the technical and commercial reach with economies of scale that have been developed over time for conventional materials such as wood and aluminium.

- True pricing, applying shadow prices for environmental costs and social impact, can stimulate the introduction of biocomposites. Unfortunately, the sustainability value of bio-based materials is not fully recognized in the Environmental Cost Indicators (ECI), as the applicable Life Cycle Assessment (LCA) calculation rules are such that long-term carbon sequestration in products does not count in the end-to-end carbon footprint.

- Although often demonstrably more sustainable, the use of bio-based composites is not (yet) widespread. A traffic sign with a base of biocomposite is about 30% more expensive than an aluminium traffic sign. Aluminium prices have been rising because of energy cost, but the production costs of bio-composites are equally impacted, moreover by the rising cost of labour.

Outcome of assessments

LCA and EPDs for the new materials are not yet available. In the Netherlands, to include a material in the ECI of a building, this material must be included in the National Environmental Database (NMD, 2020). This requires a standardized and often quite costly LCA study of the material. These can only be pursued for selected materials with sufficient technical maturity and potential. However, the carbon footprint analysis showed promising results, especially for the fully bio-based variants, which show negative kg CO2 eq when CO2 sequestration is included.

A human health quantitative risk assessment has been performed based on Inductively Coupled Plasma Mass Spectrometry (ICP-MS) analysis for heavy metals and dangerous substances such as resin compounds (e.g., styrene and furfuryl alcohol) with QCRA and QMRA methods used in both deterministic and stochastic modes. Additionally, environmental quantitative risk assessment has been performed based on data collected during the laboratory leaching tests conducted at TU Delft and following the European guidelines for environmental risk assessment framework using the ratio PEC/PNEC to assess risks. Where PEC is the Predicted Effects Concentrations, represented by leaching tests results, and PNEC is the Predicted No-Effects Concentration, collected from ECHA (European Chemicals Agency) database. Then, a leaching-oriented Environmental Risk Analysis (ERA) for bank protection elements made of new bio-composite materials was performed. This assessment took into account the actual flow rate in the canal and the canal dimensions, in addition to leaching tests and other data. In the practical case, all leaching values stayed below the applicable risk limits.

Legislation and policy recommendations

Relevant EU legislation (direct or indirect) includes: EU Green Deal, Circular Economy Action Plan (COM/2020/98 final), EU Waste Framework Directive (2008/98/EC), EU Urban Waste Water Treatment Directive, EU Drinking Water Directive, EU Water Framework Directive, EN 15804:2012+A2:2019, product category rules (PCR) for Type III environmental declarations for construction products and services, EU Nature Restoration Law, Water Framework Directive, (Forthcoming) EU policy framework on bio-based, biodegradable and compostable plastics.

Relevant national (NL) legislation and policies includes: Environmental Management Act (Wet Milieubeheer), which includes NL implementation of the Waste Directive (ch.10), Water Act (Water Wet), among others regulates water management systems and explains the tasks and organisation of the water authorities, National Waste Management Plan (Landelijk Afvalbeheerplan (LAP), a policy framework for waste in the Dutch circular economy), Green Deal Raw Materials ‐ Union of Water Authorities (Green Deal Grondstoffen Unie van Waterschappen, C‐174), attempts to strengthen the economy while simultaneously decreasing the dependence on fossil energy and scarce natural resources. It does so by promoting and increasing the amount of resources from sewage water, Bio-based Delta (NL).

The Dutch Minister of Public Housing and Spatial Planning) has expressed the need to focus more closely on the materials transition (from CO2-intensive and linear materials to climate-positive and circular materials). In a letter to the Parliament (Dec 23, 2022) he stated an intent to 1. encourage bio-based construction by introducing a CO2 requirement to also value the carbon that is captured in bio-based materials and 2. give an extra impulse to the upscaling of the application of bio-based raw materials. Later (June 12, 2023) he appealed for a building materials agreement with the construction sector which among others should cater for setting up new chains for bio-based and circular construction. Progress may now be affected by the caretaker status of the cabinet and upcoming elections.