Description

The WWTP of Altenrhein operates residential drainage-, wastewater- and sludge treatment of 17 municipalities in two federal states (St. Gallen and Appenzell-Ausserrhoden).

The treated water reaches Lake of Constance via the mouth of the Old Rhine. Both Lake of Constance and the Old Rhine are considered priority water bodies for protection. Lake of Constance also serves as a drinking water reservoir. The topographical conditions around these 17 municipalities vary greatly which makes the water transportation more challenging. For this reason, special structures are required. Sludge that is being treated in Altenrhein originates from their own water treatment and is also being transported to the site by other WWTP of Eastern Switzerland. The WWTP of Altenrhein (AVA) has advanced energy-efficient sludge management technologies for 300.000 pe of sludge: sludge is dried on site and is co-incinerated in cement works. The heat for sludge drying is generated by burning of sewage gas and by heat recovery from wastewater using heat pumps. AVA took a full-scale removal of micropollutants by ozonation and active carbon adsporption into operation in 2019 and a ammonia membrane stripping unit from sludge dewatering emplying an innovative membrane contactor with a novel low fouling membrane module in 2021 a total investment of EUR 20 Mio in innovative technologies. After the project AVA will have a clear idea of the technical and financial feasibility of on-site activated carbon regeneration and production of fresh activated carbon using locally available sludge and biomass. Long-term experience with full-scale installations for micropollutant removal and N recovery gained with the installations at Altenrhein will reduce investment risks, enhance chances of replicability. AVA also gathers the all necessary information to take an investment decision regarding the construction of a P-K fertilizer production unit. This novel thermochemical process transforms sewage sludge into a market grade P-K-fertilizer. Thereby heavy metals are partly removed and the fully plant available mineral phase CaKPO4 is produced. The process has been piloted in a large-scale pilot to gain further operational experience.

Applied technologies

Technology performance and best practices

Ammonium sulphate production (membrane stripping/HFMC)

In Altenrhein, also a HFMC was tested, however in a side stream for the concentrate of dewatered digestate at TRL 8. The recovery rate was 75% in the pilot plant. Hence, the recovery of a full-scale system (305 000 PE) of 66 t N/a can be expected for Altenrhein. This corresponds to 11% of the nitrogen inflow load to the WWTP. More details can be found in D1.5.

Granular activated carbon (GAC) production via pyrolysis

In Altenrhein, a pyrolysis process was tested as a side stream treatment of dried digestate to produce granular activated carbon. The renewable sewage sludge GAC has only a fraction of the active surface of the conventional GAC and also the pore volume is smaller. It has a good hardness suggesting good resistance to typical stresses in fixed bed contactors. The recovery rate was 50% GAC and 50% pyrolysis gas. The GAC produced from sludge was suitable for a pretreatment to remove micropollutants upstream of a conventional GAC filter to prolong its lifetime. More details can be found in D1.5.

PK-fertiliser production via thermal treatment

In Altenrhein, a thermal treatment was tested using dried digestate as side stream technology. Its TRL reached 8 and the recovery rate ranged between 90% and 100%. Since this treatment does only partly remove heavy metals, a detailed characterisation of the feed stream is necessary and an application using “clean“ digestate or waste streams from the food industry might be even more beneficial. Using digestate from a municipal WWTP as feed stream, 0.95 kg P/h was achieved in the pilot plant. This corresponds to the recovery of 390 t P/a for a 305 000 PE full-scale plant. Those correspond to 12% of the influent phosphorus load of the WWTP. More details can be found in D1.5.

Outcome of assessments

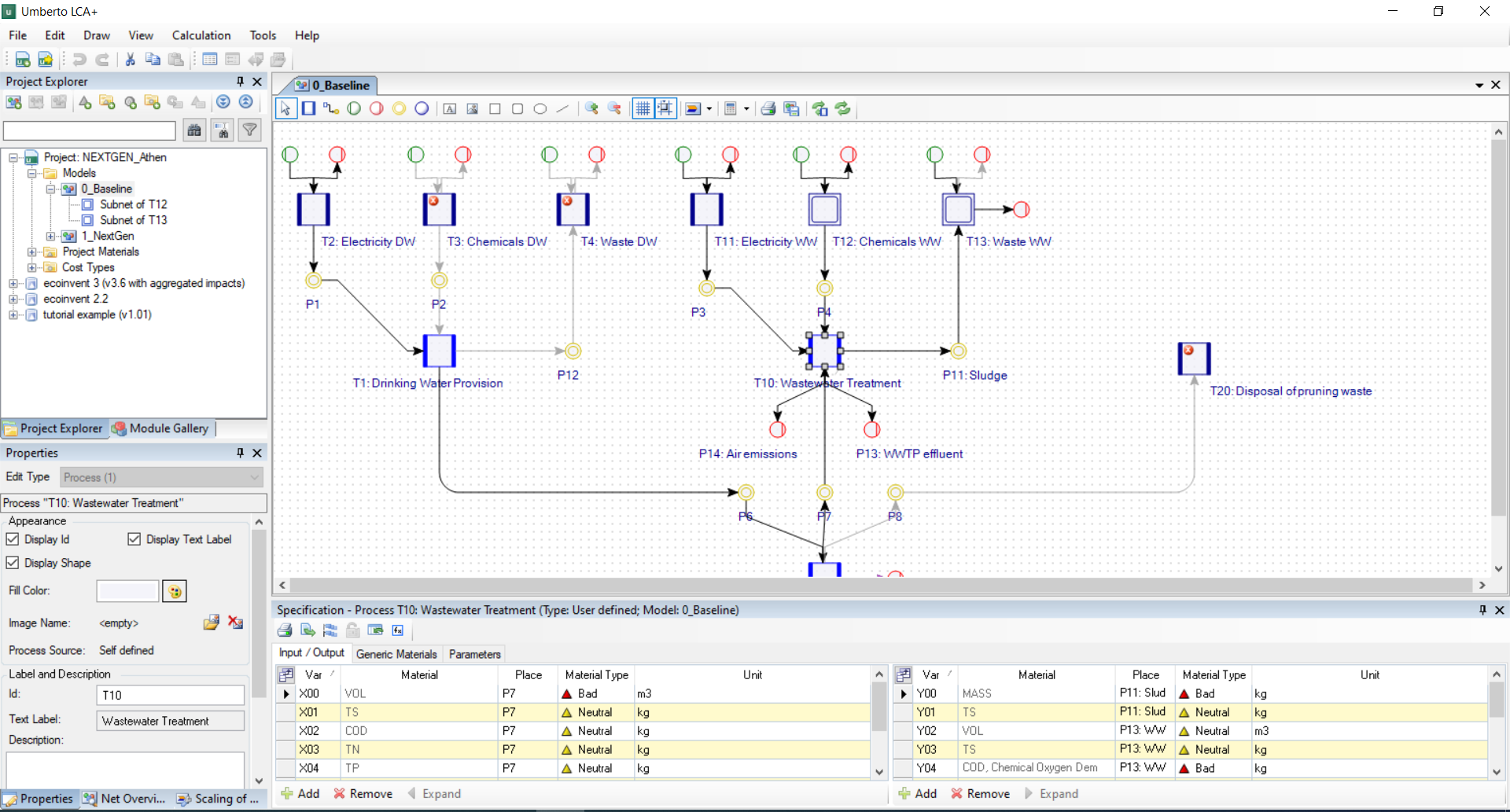

Life cycle assessment

Membrane stripping helps to reduce high N loads to the WWTP and recovers nitrogen fertilizer, also reducing N2O emissions from wastewater treatment significantly. The Pyrophos process is able to recover P from sludge in a plant-available form and with a heat surplus, further reducing the CO2e footprint of the plant. Renewable activated carbon from sludge could be used to replace fossil based alternatives, but related savings in CO2e are off-set by frequent regeneration and higher ozone dose required. Further LCA results can be found in D2.1

Life cycle costing & cost effectiveness analysis

Using renewable GAC comes with an additional cost and perhaps more importantly does not contribute to the objective of this technology: climate mitigation. However, a regional regeneration for Swiss GAC users with replenishment of material losses directly from their own sewage sludge is an interesting option for independent circular operation with potentially significant costs reduction making this option economically profitable. Ammonia stripping is also not profitable but successfully performs its intended system service of reducing nutrient load in the biological treatment and thus mitigating climate heating. Further LCC and CEA results can be found in D2.2.

Legislation and policy recommendations

In NextGen, we analysed the policy and regulatory landscape to identify relevant opportunities for and barriers to upscaling circular economy in the water sector. Our recommendations, targeted at the revised Urban Wastewater Treatment Directive, are summarised in our policy brief. These recommendations focus on creating meaningful incentives and policy drivers towards circular systems (e.g., through energy and carbon neutrality targets, and additional guidance on water recycling) and simplifying the route to market for recovered products (e.g., fertilisers and other materials). Check out our policy brief.

Applied product

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…