Description

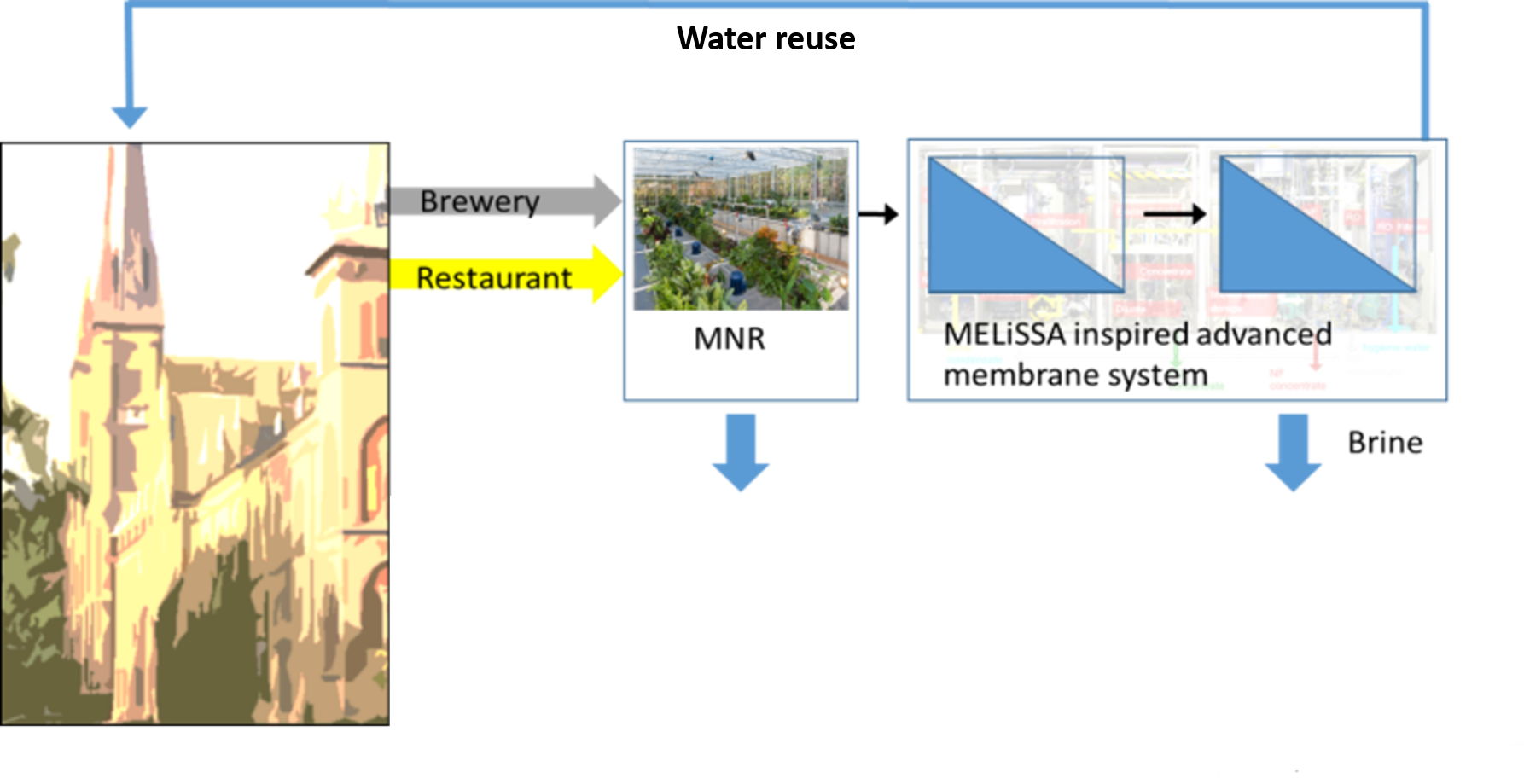

The Koningshoeven BioMakery is a biological wastewater treatment system based on modular and functional reactor based ecological engineering. The BioMakery is powered by Metabolic Network Reactor (MNR) technology, which uses 2-3,000 different species of organisms ranging from bacteria to higher level organisms such as plants. The BioMakery serves as a test facility for advanced circular space technology developed within the micro-ecological life support system alternative (MELiSSA) program of ESA. SEMiLLA formerly known as IPStar has a mandate to implement this technology in civil society. Coupling MNR with MELiSSA advanced separation and photobioreaction based technologies, reusable process and/or irrigation water will be produced, while also growing biomass that can be used as slow-release fertilizer for the plant nursery, as fish fodder, or as human food.

Applied technologies

Technology performance and best practices

Metabolic Network Reactor (MNR) coupled to a Micro-Ecologial Life Support System Alternative (MELiSSA) advanced separation systems (MF/RO)

Before the installation of the MNR and MELiSSA systems the effluent from the brewery was released into the public sewerage network of Tilburg. The treatment took place in the Tilburg municipal wastewater treatment plant, located approximately 9km from the brewery, at the opposite end of the city. The transport of high strength wastewater over long distances can cause issues in the sewer lines, such as deposition of solids and anaerobic decomposition resulting in emission of odors and corrosive gases.

The performance expected of the MNR unit was with a 99% of water yield, a 97.6%, 99.7% and 99% of BOD, COD and turbidity were removed. Assuming stable operation of the MNR, high quality effluent could be produced. However, due to lower than expected MNR effluent water quality it was not possible to determine KPIs in terms of flux, energy consumption for the membrane systems. Quality parameters were at or above expectations after membrane filtration. For example, the conductivity reduction rate was 95%. The turbidity reduction rate was 25%. The COD reduction is equal to 90%. More details are provided in D1.3.

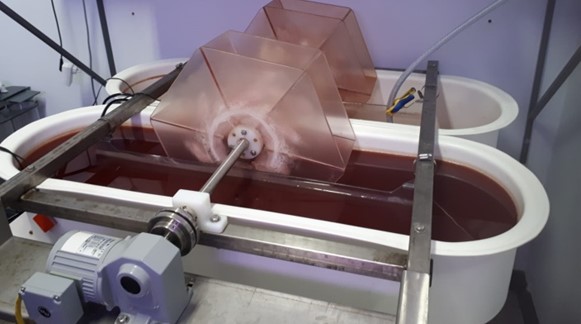

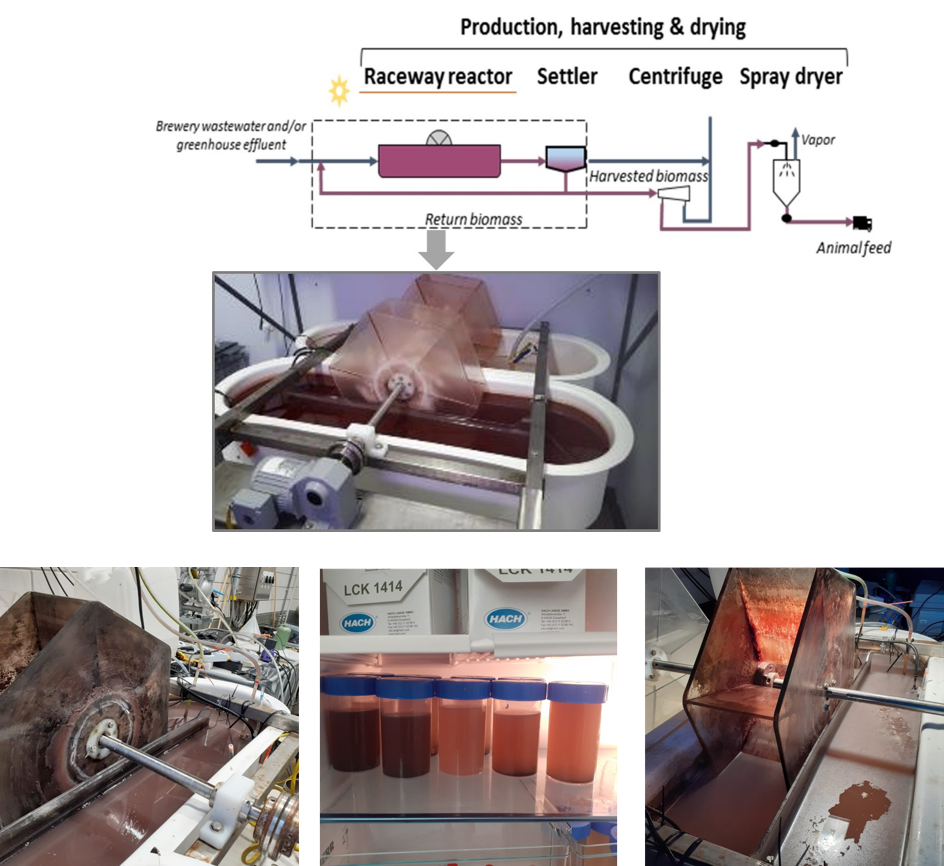

Protein production from wastewater

In La Trappe (NL), a photobioreactor was demonstrated to treat brewery wastewater and urine in a mainstream to produce proteins that can be used as a slow release fertiliser. In general, this technology is also capable to produce proteins that can be used as fodder or even food additive. The TRL of the technology is still low between 5 and 6 and further investigations are needed. The recovery rates were 38% for COD, 20% for N and 25% for P. The photobioreactor produced roughly 0.48 g TSS biomass per litre wastewater. This corresponds to a production of around 276 to 575 kg of dried biomass per year to be used as a slow release fertiliser. In NextGen, the proteins were successfully tested as a slow release fertiliser to grow microgreens. Furthermore, this technology is also very well suited to treat concentrates from membrane treatments. More details are provided in D1.5.

Outcome of assessments

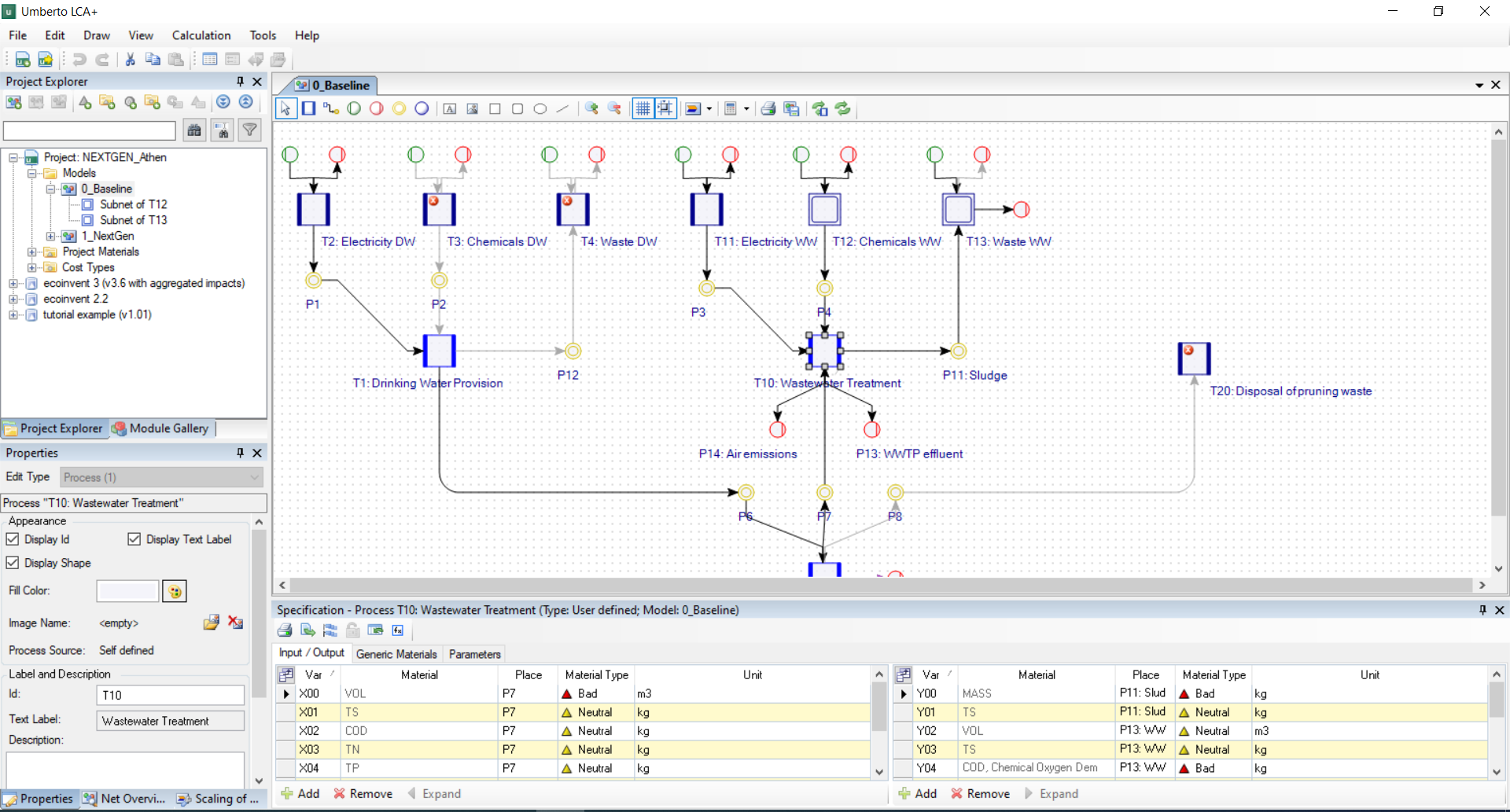

Life cycle assessment

The metabolic network reactor can deliver a high effluent quality, but its energy and chemical demand should be further optimised to compete with other benchmark technology. MNR effluent can be treated with capillary nanofiltration membranes to enable reuse as process water in the brewery, decreasing water stress on local groundwater resources at a reasonable increase in CO2e footprint. Further LCA results can be found in D2.1

Life cycle costing & cost effectiveness analysis

The implementation of a metabolic network reactor, complemented by microfiltration and dissolved air flotation for brewery effluent treatment can be considered cost effective compared to the past baseline situation, where the brewery paid a specific price per volume of brewery effluent discharged to the local WWTP. The biggest cost drivers of this NextGen circular solution are CAPEX, insurance & maintenance and energy input. Further LCC and CEA results can be found in D2.2

Legislation and policy recommendations

In NextGen, we analysed the policy and regulatory landscape to identify relevant opportunities for and barriers to upscaling circular economy in the water sector. Our recommendations, targeted at the revised Urban Wastewater Treatment Directive, are summarised in our policy brief. These recommendations focus on creating meaningful incentives and policy drivers towards circular systems (e.g., through energy and carbon neutrality targets, and additional guidance on water recycling) and simplifying the route to market for recovered products (e.g., fertilisers and other materials). Check out our policy brief.

Applied product

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…