Description

The Timisoara water system is operated by AQUATIM SA (public company). The regional utility is offering services for drinking water (28 water treatment plants) and operate regional wastewater treatment plants(22 in their area) as well as leakage reductions in the distribution systems.The water coming from the city wastewater collection system enters the waste water treatment plant through four main sewers and goes through the mechanical and advanced biological treatment facilities, prior to be discharged into the Bega river. The mechanical treatment phase includes four coarse and fine screens, equipped with cleaning, waste compaction and storage systems.

When the sewage stream exceeds the designed capacity limit, the excess is taken by four first flush storage tanks. When this limit is also exceeded, the stream is screened by an automated cleaned rack and then pumped into the Bega river, by seven Flygt pumps, at a rate of 3,500 l/s.The biological treatment phase includes the nitrification-denitrification process and the chemical treatment for the removal of phosphor. The tank has a capacity of 106,600 cubic meters and is divided into four sections. The removal of phosphor is achieved by chemical treatment, using the ferrous sulphate as coagulation agent and a dosing and injection system. The biomass is separated in eight secondary circular settlers, with diameters of 40-48 m. In the project CS#10, the project will tackle the thermochemical conversion of sewage sludge and will study the water reuse for several industries in Timisoara.

At the Timisoara WWTP, pilot-scale testing of thermochemical conversion of sludge will be implemented. The technology demonstrated will be pyrolysis (via thermo-catalytic reforming) of aerobically stabilised sewage sludge to produce biochar, oil and gas. These products can be exploited energetically as fuel or soil enhancing agent or sorbent. The water reuse of the secondary effluent of the Timisoara WWTP will be studied, looking into the feasibility for urban (e.g. street cleaning, park irrigation), industrial and agricultural (farm land irrigation) applications.

For the water re-use study, the local project partners will map potential users by performing a water demand analysis of municipality, industrial and agricultural users,will describe the water quality issues related to sectoral water reuse and suggest treatment options, , and will assess the different environmental and economic/financial implications that could result from water re-use.

Technology performance and best practices

Feasibility study on reclaimed water production at regional level

The study of water reuse in the Timişoara Metropolitan area shows that a more profound cost-benefit analysis understanding of the economic viability and opportunity of water reuse systems is needed. The involvement of various stakeholders available locally is also important, along with understanding the capacity of water resources management and societal involvement. Even though water reuse is currently implemented in some European countries, water reuse projects will only succeed in Romania if water-related and industrial authorities along with users will understand and apply the Integrated Water Resources Management (IRWM) concept. The three cases investigated showed that wastewater reuse is not easy to implement in the current way of placing the WWTPs - downstream and outside settlements. The cost of return the reclaimed water back in the city/localities is going to be too high due to the pumping needed. Also, returning reclaimed water back where would be needed requires expensive solutions to cross the city old area.

Prior to implementing circular economy solutions for water recovery at full-scale and at a local or regional revel, it is recommended to conduct a feasibility evaluation. The study carried out in Timişoara also integrated potential stakeholders which could benefit from the implementation of advanced treatments for the wastewater in order to obtain the reclaimed water for reuse, established collaboration with the local and regional administration, and conducted dissemination and communication activities to increase the knowledge and awareness on water scarcity, water reuse and circular economy. The study focused on recovering 100% of the current WWTP effluent (10 800 m3/h). Three clients for reclaimed water use, as well as the cost to build the reclaimed water distribution network and the water quality required for the selected uses, were identified. More details are provided in D1.3.

Biochar, oil and gas production via sludge pyrolysis

In Timișoara, a pyrolysis process was tested as a side stream treatment of dried digestate to produce pyrolysis gas, oil as well as biochar. The recovery rate was 18% gas, 2% oil and 63% biochar. The pyrolysis batch experiments with the sludge originating from Timișoara showed a potential to subtitute around 3100 m³ natural gas/d with an up-scaled system. More details are provided in D1.5.

Outcome of assessments

Quantitative microbial risk assessment (QMRA)

At the case study in Timissoara, the QMRA tool was used to explore the potential for the reuse of treated wastewater for agricultural irrigation. More details can be found in D2.1.

Legislation and policy recommendations

In NextGen, we analysed the policy and regulatory landscape to identify relevant opportunities for and barriers to upscaling circular economy in the water sector. Our recommendations, targeted at the revised Urban Wastewater Treatment Directive, are summarised in our policy brief. These recommendations focus on creating meaningful incentives and policy drivers towards circular systems (e.g., through energy and carbon neutrality targets, and additional guidance on water recycling) and simplifying the route to market for recovered products (e.g., fertilisers and other materials). Check out our policy brief.

Applied product

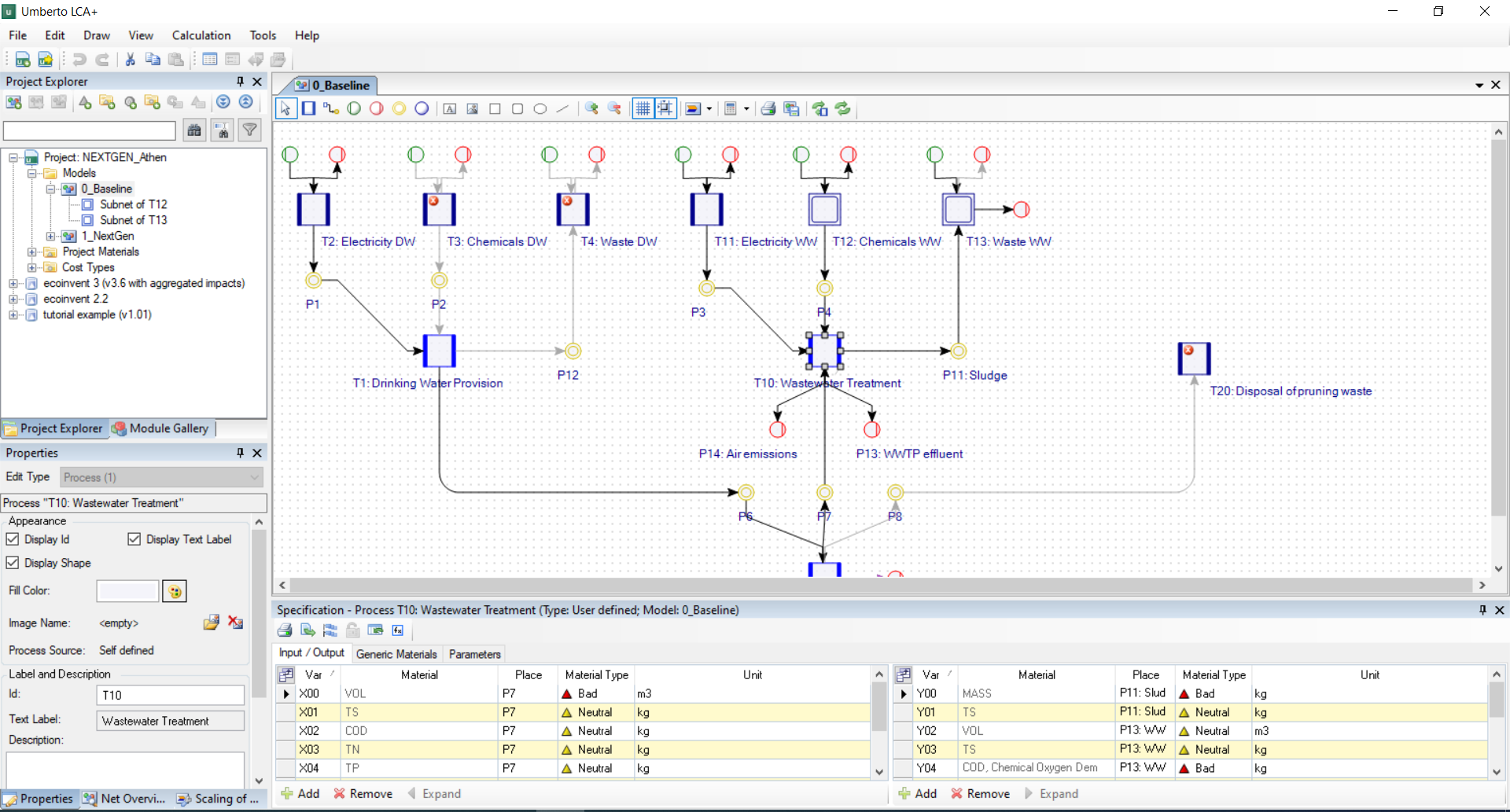

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…