Description

Spernal WWTP serves the towns of Redditch and Studley located approximately 24 km south of Birmingham (UK). The area has a residential population of approximately 85,000. The treated effluent is currently discharged to the River Arrow, which is designated as a sensitive area under the Urban Wastewater Treatment Directive (UWWTD) and has an overall water body status of moderate under the Water Framework Directive (WFD). Sludge from the site and other local rural works is treated in conventional anaerobic digesters and dewatered before being recycled to local farmland and industries. The biogas produced by digesters is burnt in combined heat and power (CHP) engines to produce heat and electricity.

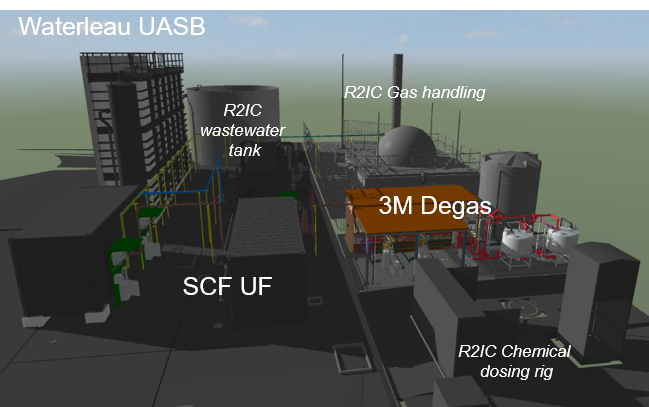

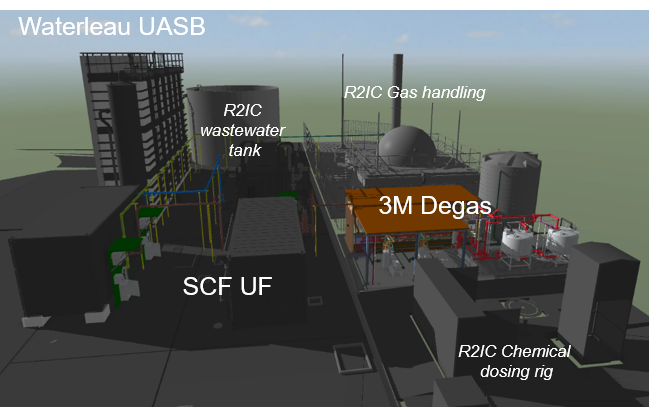

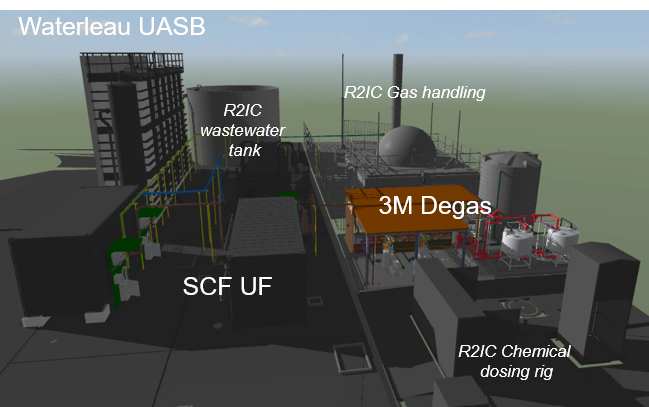

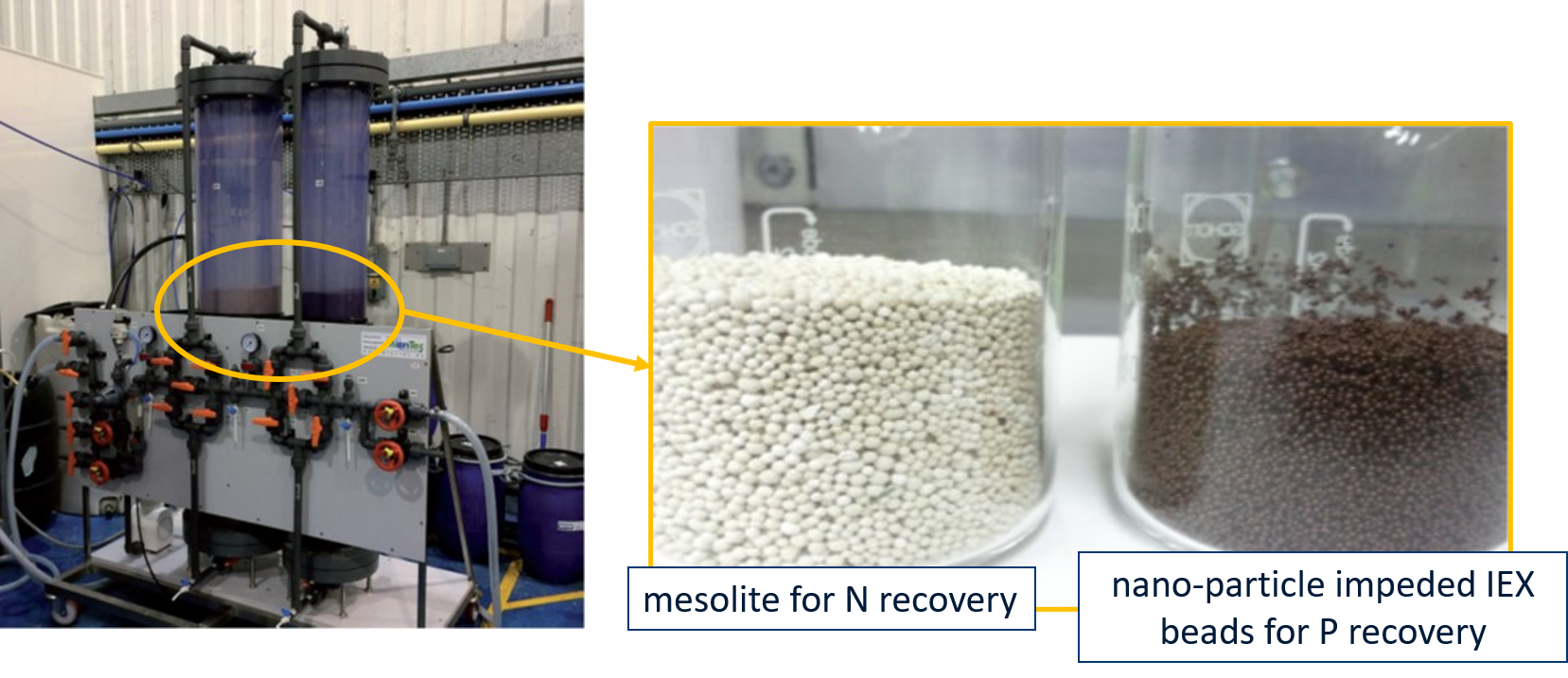

A multi-stream technology demonstration plant incorporates an anaerobic membrane bioreactor (AnMBR) complete with a membrane degassing unit to recover dissolved methane for water and energy reuse, and a pilot scale nutrient adsorption step for nitrogen and phosphorus recovery. Through such demonstration to close the water, energy and materials cycles, the necessary data to assess the benefits of the technologies will be provided.

Applied technologies

Technology performance and best practices

Anaerobic membrane bioreactor (AnMBR)

Solids management in the AnMBR is of vital importance, as these must be retained in the UASB reactor for as long as possible to go through hydrolysis followed by the 3 other stages of anaerobic digestion and ultimately result in biogas production. Further, the solids should not find their way to the UF to avoid fouling issues.

The AnMBR operational efficiency achieved in this study was comparable to previous studies with variable influent municipal wastewater values for COD of 221-455 mg/L and TSS of 45-479 mg/L. The removal rates achieved for the COD and BOD5 were still lower compared to other studies that obtained 83 ± 7% and 90 ± 6%, respectively, but similar values are expected once the AnMBR reaches stable operation. A granular sludge inoculated AnMBR also can achieve an sCOD removal of 43 ± 15%, also similar to this study’s results. The removal efficiency of a self-forming hollow fibre dynamic membrane was only around 42% and 34% for TSS and VSS. The similar reactors design of this study to previous studies emphasise the validity of the results and work performed. The operational temperature range was also similar to previous studies: operated at 18 ± 2ºC and 16.3 ± 3.7ºC.

Regardless of the high COD influent in the systems, the methane yield reported was considered average. This was mainly because no solids could escape the system and hydrolysis was maximised during operation, which in turn ensured methane yields were high. More detailed results can be found in D1.3.

Decentralized energy recovery from AnMBR

Decentralized energy recovery from an anaerobic membrane reactor (AnMBR) combined with a methane degassing system was tested at the Spernal wastewater treatment plant (UK). The membrane degassing system demonstrated in Spernal can potentially recover methane from the AnMBR effluent to a dissolved methane concentration of 0.14 mg/L from an initial concentration of 20 mg/L (99% removal, designed values). The membranes are designed to operate at 2 Nm3/h gas at 60 mbar. In addition, liquid ring vacuum pump technology was chosen to generate the vacuum. This system has several benefits, including the potential for energy neutrality, compact size with a low carbon footprint and low operation costs. The energy production on the Spernal demonstrator originates from the biogas produced in the anaerobic membrane bioreactor (AnMBR). On average the biogas yield recorded was 0.15 m3 CH4/kg COD removed, this includes the dissolved methane part of the biogas production. As presented in Table 1, two scenarios were considered: (a) generation of electricity and heat via CHP and (b) upgrading of biogas for grid injection. Based on the scenarios, the theoretically recoverable energy was estimated for a capacity of 200 m3/day (i.e., AnMBR effluent as a feed). Thus, it was expected to produce 44 kWh/day electricity and ~ 50kWh heat/d (assuming around 15% losses) for scenario (a) and 108 kWh/d of biogas for scenario (b). However, during the NextGen project, the methane degassing system has not been capable of recovering dissolved methane from AnMBR effluent that can be used as an energy source. This was mainly due to the influent wastewater quality, in particular sulphate. At present, the methane degassing system is given more attention by engineers/operators to reach higher TRL. More detailed results can be found in D1.4.

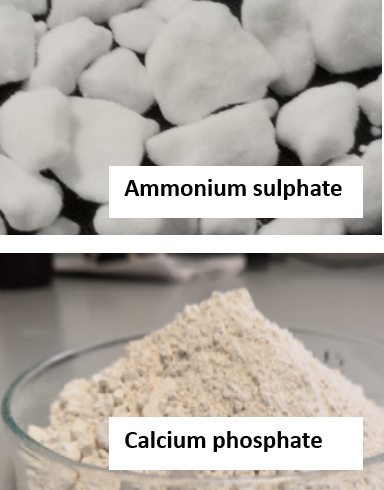

Nutrient recovery (ammonium sulphate and hydroxyapatite)

In Spernal, ammonium sulphate and hydroxyapatite were produced as a mainstream treatment using the effluent of an anaerobic membrane bioreactor combined with an ion exchanger. For ammonia sulphate production, the TRL reached TRL 6 suggesting, that further investigations are necessary prior to its replication at full-scale. The system was applied in the effluent of an anaerobic membrane bioreactor as a mainstream technology. It consisted of an ion exchanger to concentrate the ammonium and a hollow fibre membrane contactor (HFMC) for ammonia stripping and ammonium sulphate production. The recovery rates for the ion exchanger and the HFMC were >80% and > 95%, respectively, resulting in a nitrogen recovery rate higher than 76%. Based on those results, the production of ammonium sulphate in a full-scale system for 100 000 PE is assumed to result in the recovery of 320 t N/a. This corresponds to 88% of the inflow nitrogen load to the WWTP.

The ion exchanger was also used to concentrate the phosphate concentration in order to precipitate the phosphate as hydroxyapatite in the subsequent precipitator. A TRL of 7 was reached suggesting to further optimise the system. The recovery rates for the ion exchanger and the precipitator were >80% and > 90%, respectively. Based on those results, a full-scale system (100 000 PE) can recover 61 t P/a, what corresponds to 80% of the P load in the influent of the WWTP. More detailed results can be found in D1.5.

Outcome of assessments

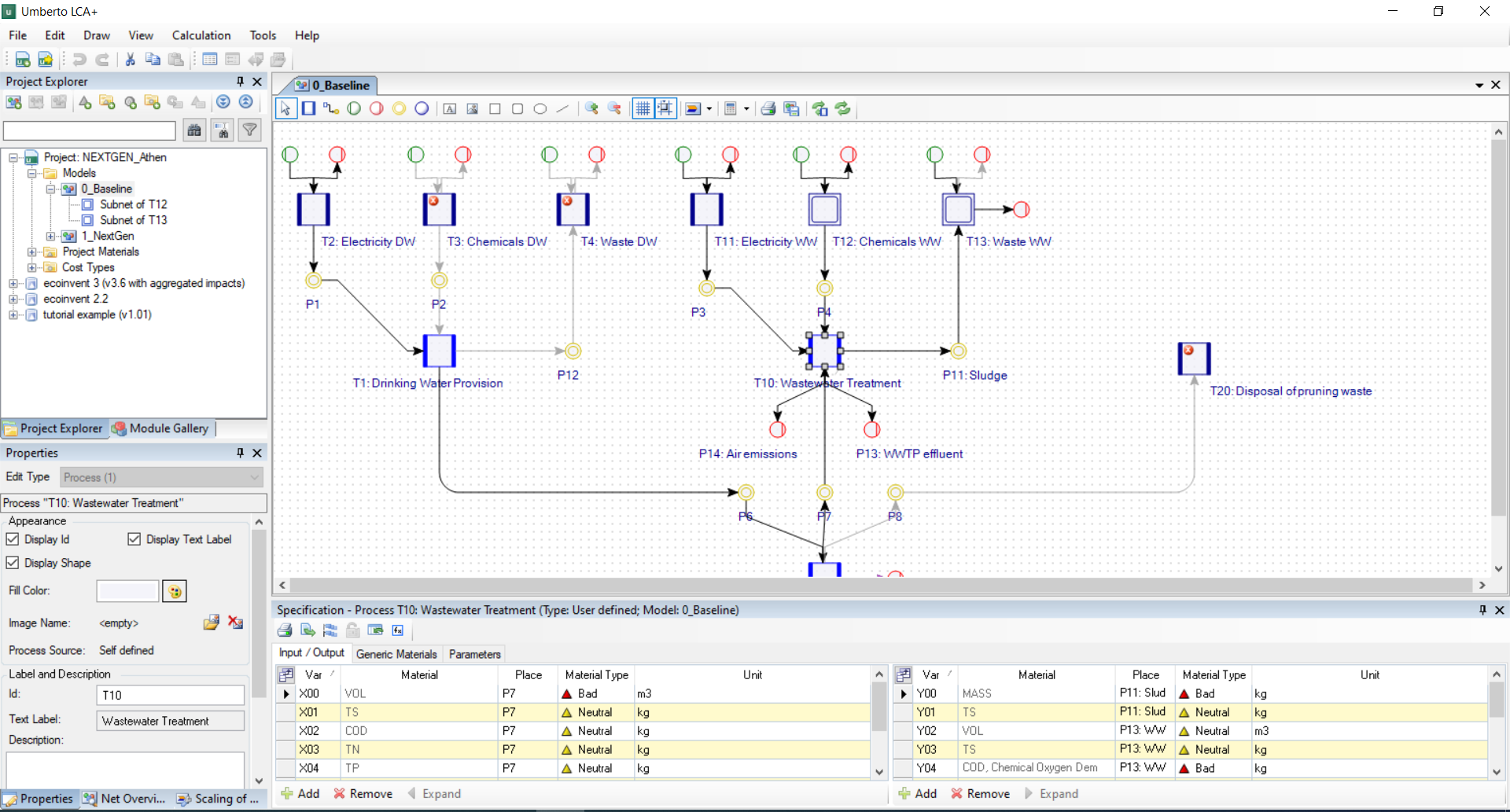

Life cycle assessment

Anaerobic treatment of wastewater is feasible and has a superior energy balance to aerobic treatment. However, potentially high energy demand of the membranes and degassing step would fully off-set this benefit and should be further optimised. Ion exchange for nutrient recovery can recycle most N and P at neutral CO2e footprint, and fully avoids N2O emissions from the biological stage. Effluent of the anaerobic membrane process seems highly suitable for fertigation, which leads to further CO2e savings if water and nutrients are efficiently utilised. Further LCA results can be found in D2.1.

Life cycle costing & cost effectiveness analysis

In view of wastewater treatment and energy recovery, the anaerobic treatment of municipal wastewater in a membrane bioreactor (AnMBR) can be considered cost effective regarding OPEX compared to a typical UK WWTP with biological nutrient removal and iron dosing. The energy and sludge disposal cost savings can more than offset the additional chemical/material costs. The application of ion exchange should be further optimised regarding OPEX as related chemical input costs are higher than fertiliser revenues. Further LCC and CEA results can be found in D2.2.

Chemical risk assessment for the application of renewable fertilisers

In Spernal, phosphorus is recovered as calcium phosphate in a pilot scale for agricultural application. Several inorganic substances (As, Cd, Cr, Cu, Pb, Hg, Ni, Zn), as well as Benzo(a)pyrene were measured below the limit of detection. A long-term application of the fertiliser did not result in a high risk to soil or groundwater ecosystems. Detailed results can be found in D2.1.

Legislation and policy recommendations

In NextGen, we analysed the policy and regulatory landscape to identify relevant opportunities for and barriers to upscaling circular economy in the water sector. Our recommendations, targeted at the revised Urban Wastewater Treatment Directive, are summarised in our policy brief. These recommendations focus on creating meaningful incentives and policy drivers towards circular systems (e.g., through energy and carbon neutrality targets, and additional guidance on water recycling) and simplifying the route to market for recovered products (e.g., fertilisers and other materials). Check out our policy brief.

Applied products

AquaNES QMRA tool for water reuse scenarios

Water quality assessment and associated risk assessment is essential for the evaluation of water treatment. It is not a…

NEXTGEN + ULTIMATE Life Cycle Assessment

Life Cycle Assessment is a standardized framework (ISO 14040) for assessing the potential environmental impacts of a pr…